Custom Parchment Paper for Your Branding

Whether you are a professional chef, a homemaker, or a restaurant owner, you already understand the importance of custom food wraps. These wraps help protect food, enhance presentation, and support sustainable packaging goals. Among all available options, custom parchment paper stands out as one of the most versatile and reliable food-wrapping solutions.

“Custom” means more than just paper—it refers to personalized designs, sizes, and colors that represent your brand identity. If you are looking for a premium food wrap that combines functionality, sustainability, and branding, Custom Printed Paper is the ideal choice. Our competitive pricing, high-quality materials, sustainability compliance, and strong branding potential make custom parchment paper a valuable addition to your packaging strategy.

Personalized parchment paper has multiple uses in cooking and food handling. From wrapping food items to preventing dough from sticking to baking trays, it delivers excellent performance in every application.

What Is Custom Parchment Paper?

Custom parchment paper is a food-grade specialty paper that is acid-treated and coated with silicone to provide non-stick, heat-resistant, and greaseproof properties. Instead of using plain or generic sheets, brands now prefer custom parchment paper for food that can be produced in specific dimensions, colors, and printed designs.

At our company, we manufacture parchment paper with custom sizing and brand-specific printing, allowing you to create a personalized food presentation that leaves a lasting impression on customers. The chemical treatment and silicone coating make this paper highly resistant to temperature, making it an excellent choice for baking, cooking, and food wrapping.

How to Identify Parchment Paper Physically

Parchment paper can be easily identified by its unique physical characteristics:

-

Smooth, slightly waxy surface due to silicone coating

-

Translucent appearance with a subtle sheen

-

Thicker texture that resists tearing

-

Non-stick surface that prevents grease and ink from bleeding through

These qualities make parchment paper dependable for both professional kitchens and home use.

Materials and Coatings

Our custom parchment paper sheets are manufactured using premium-quality wood pulp that undergoes several refinement processes. This ensures the paper remains strong, grease-resistant, and non-stick.

After production, a silicone coating is applied, enabling the paper to withstand temperatures up to 450°F (232°C). As a trusted parchment paper sheets wholesale provider, our goal is not only to ensure heat resistance but also to prevent paper breakage and flavor transfer.

Benefits of Silicone Coating

-

Water resistance

-

Grease resistance

-

Excellent non-stick performance

This is why parchment paper for baking is widely used. Its moisture-resistant nature also makes it ideal for wrapping hot sandwiches and burgers without causing sogginess.

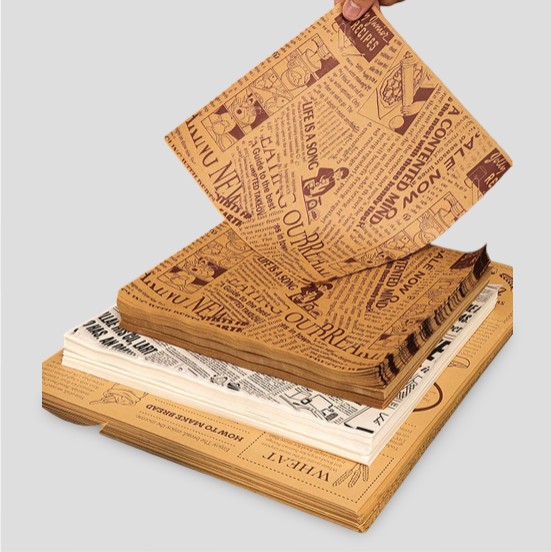

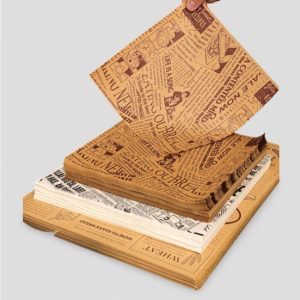

We mainly offer white and brown custom parchment paper options.

Difference Between Brown and White Parchment Paper

The primary difference between brown and white parchment paper lies in appearance and processing.

-

Brown parchment paper retains its natural kraft color and provides a rustic, eco-friendly look. It is treated with zinc chloride and sulfuric acid to dissolve paper fibers and enhance non-stick and heat-resistant properties.

-

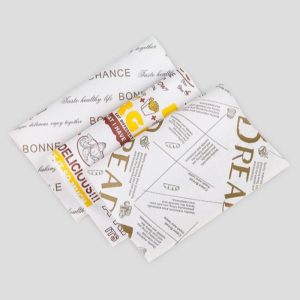

White parchment paper goes through the same treatment, followed by an additional bleaching process using chlorine or chlorine dioxide for a cleaner, refined appearance.

Manufacturing Process of Parchment Paper

1. Pulping

Wood or plant fibers are mixed with water and chemicals to form a soft, semi-solid pulp.

2. Beating and Refining

The pulp is refined to improve smoothness, strength, and flexibility.

3. Paper Formation

The pulp is spread over large screens, excess water is drained, and fibers bond to form continuous paper sheets.

4. Sulfuric Acid Treatment

This process enhances durability, translucency, and heat resistance.

5. Neutralization and Drying

Excess acid is neutralized using an alkaline solution, and the paper is dried.

6. Silicone Coating

A final silicone layer provides superior non-stick properties and high heat tolerance.

Types of Custom Printing on Parchment Paper

We offer multiple custom parchment paper printing options to support branding and premium food presentation.

Flexographic Printing

Ideal for large production runs and intricate designs, delivering sharp and consistent results.

Digital Printing

Best for short runs with detailed graphics and vibrant colors. Cost-effective for smaller quantities.

Offset Printing

Perfect for high-volume production, offering excellent color accuracy and consistency.

With these techniques, you can choose colors that match your brand—such as pastel parchment paper for bakeries or bold colors for premium food packaging.

Benefits of High-Speed Printing and Sustainable Inks

High-Speed Printing

Offset and digital printing ensure fast turnaround times, especially for bulk orders.

Environment-Friendly Inks

We use water-based and soy-based inks that are non-toxic, food-safe, and eco-friendly.